Function :

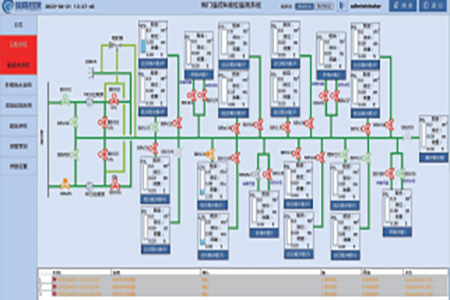

The Valve Remote Control System enables centralized remote operation of all controllable valves onboard. Crew members can operate the valves via

a graphical interface on the workstation display. In case of power, air, or hydraulic source failure, the system supports emergency valve operation using a

manual hydraulic pump, ensuring system reliability and rapid emergency response.

The Level Gauging System provides real-time monitoring of fluid levels in various onboard tanks (e.g., mud tanks, fuel tanks), as well as forward and

aft draft measurements. Signals collected from each sensor are transmitted to the workstation via a data acquisition unit, enabling real-time status display

and alarm handling from the control room. This ensures accurate support for vessel operation and safety.

Features :

Secure User Access :The system features a user login mechanism to effectively manage permissions and ensure operational security.

Unified Software Architecture:All industrial PCs operate with a unified version of the monitoring software, ensuring compatibility and ease of maintenance.;

Data Synchronization :The main monitoring program is installed on all workstation industrial PCs, ensuring stable and consistent data synchronization across the system.;

Real-time Monitoring: The main monitoring program enables real-time acquisition of alarm information and the operational status of key equipment, ensuring fast system response and efficient operation.;