Function :

The Monitoring And Alarm System in the engine room of the ship is an important monitoring equipment in the ship. It is an indispensable condition

to realize the automation of the engine room and even the automation of the ship. It can replace the engineers to monitor the running state of the

equipment under the relatively bad conditions, and give the sound and light alarm signal after the failure of the running equipment. After the failure is

eliminated, the failure alarm can be cancelled, and it can also be in the aut-0 mode The advanced engine room monitoring and alarm system can not

only improve the operation economy, safety and reliability, but also greatly promote the process of ship automation and the eralization of intelligent ships.

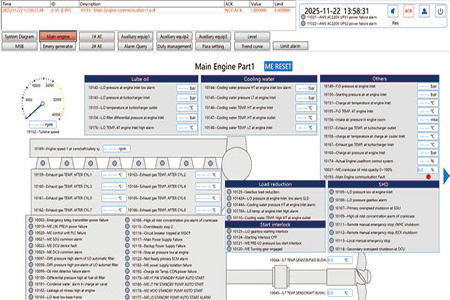

The Monitoring And Alarm System (AMS) can collect the alarm signals of the whole ship's main propulsion equipment, generator set, side thruster,

daily auxiliary equipment, various pump sets and valves and other systems or equipment, display the corresponding alarm signals with a good

human-computer interface, display the real-time and historical data of the monitoring points as required, and send the alarm signals to the extended

alarm system through the extended alarm interface, It can have data interface with integrated command system, LAN system, VDR, etc.

Features :

Parameters such as interlock, delay, deviation, change rate, upper / lower limit and alarm level can be set online.

The operation of the system does not depend on the upper computer, and the failure of the main monitoring computer does not affect the output function and the extension alarm;

With a variety of classification society certification (CCS, ABS, DNV);

Support a variety of interface customization, provide users with a variety of modification functions;

Modular design and distributed acquisition are adopted to provide users with flexible combination configuration scheme;

The core components are self controlled and compatible with Siemens PLC system;

The system is stable and reliable with dual redundant Ethernet (< 90ms switching);