Function :

The simulation training system focuses on highly simulated fault injection, creating a highly practical training environment for participants and

becoming an efficient tool for improving their practical abilities.

During the training preparation phase, the system supports pre injection of a rich variety of fault types, ranging from sudden interruptions in device

connections, abnormal sensor data jumps, to core functional module failures, parameter configuration conflicts, etc., comprehensively covering

unexpected situations that may be encountered in real scenarios. This "anticipatory" fault design allows trainees to face various difficult problems repeatedly

without worrying about the risk of real equipment damage, accumulate troubleshooting experience through trial and error, and quickly improve

emergency response capabilities.

For trainees, the training process is a 'practical rehearsal'. Faced with the complex fault environment of system construction, they must step by step

investigate equipment status, analyze abnormal data, adjust operating parameters, and even develop solutions under the pressure of multiple faults

overlapping, just like in real scenarios. This training mode completely breaks the limitations of "following the process" in traditional teaching, forcing

trainees to actively think about fault logic and related knowledge systems, truly achieving the ability to leap from "being able to operate" to "being able to

solve problems".

At the same time, the flexibility of the system makes training more targeted: it can conduct specialized training for certain types of high-frequency

faults, as well as simulate complex scenarios through multi device linkage faults to meet training objectives at different stages. Through repeated training,

trainees can not only master troubleshooting skills proficiently, but also cultivate systematic thinking and stress resistance, laying a solid foundation for

dealing with unexpected situations in real work in the future.

From the perspective of training effectiveness, this model with fault injection as the core ensures that every training session is close to the actual

combat standards, and the skill improvement of trainees is more direct and efficient. It truly achieves the goal of "one breakthrough after one practice" and

becomes a key support for rapid growth into high-level skilled talents.

Features :

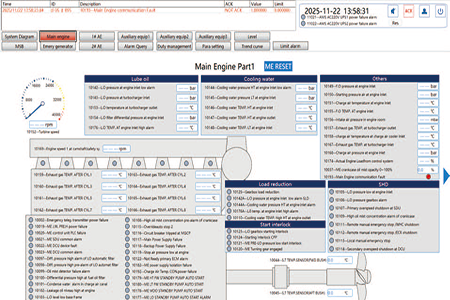

Simulated fault information;

Real time monitoring of training equipment information;

Generate score information;

Real time monitoring of the operation of the training subsystem;

Can evaluate and analyze the operations of trainees;

Compatible with a wide range of training equipment;

Real time monitoring of information from other subsystems;

Compatible with a wide range of training subsystems;