Function :

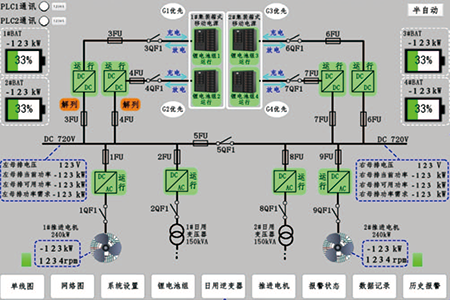

The GRF2 DC switchboard is a power distribution equipment

independently developed by our company. It connects

devices such as generators, energy storage equipment,

frequency converters, daily loads, and propulsion motors

through a DC busbar, enabling the transmission and distribution

of electrical energy. The AC power generated by the

generator is converted into DC power through a rectifier and

then connected to the DC busbar. Energy storage devices such

as batteries and super capacitors are connected to the DC

busbar either through a converter or directly, for storing and

releasing electrical energy. The frequency converter converts

the electrical energy on the DC busbar into AC or DC power

suitable for the propulsion motor and daily loads according to

the operational requirements of the ship.

Features :

The product adopts electromagnetic shielding structure design and electromagnetic interference suppression design.

The power module is designed with a versatile cooling system that supports both air and water cooling;

The main busbar is made of high-quality electrolytic copper, treated with tin plating, and placed horizontally inside the switchboard;

High protection level up to IP54

Unified structure, modular design, easy installation and maintenance, high safety and reliability;

The product adopts the company's standard ES cabinet type, featuring an aesthetically pleasing appearance and high frame strength;