Function :

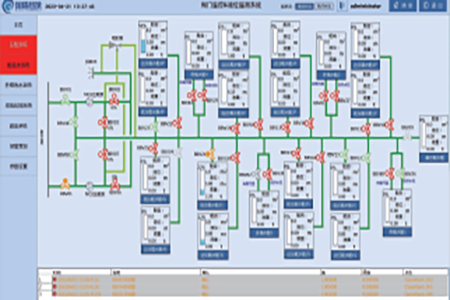

The Integrated Alarm Monitoring and Control System (IAMCS) serves as the central nervous system of modern vessel operations. It deeply

integrates three core functions—alarm generation/management, real-time monitoring of equipment status/parameters, and remote/automatic

control—across the entire vessel (including engine rooms, decks, cargo systems, navigation, and safety systems) into a unified intelligent platform.

Through an intuitive Human-Machine Interface (HMI), it centrally displays all information, comprehensively processes vessel-wide alarms utilizing

intelligent alarm prioritization, filtering, and historical logging. In AUT-0 (unmanned machinery space) mode, it enables remote operation of critical

equipment, complex automatic control logic (such as pump group switching and closed-loop control), and safety interlocks, significantly enhancing

vessel safety and automation levels.

The core value of IAMCS lies in its high integration, control capability, and intelligence. It seamlessly integrates numerous onboard subsystems

(e.g., engine room automation, power management, cargo control, fire detection systems) through standard protocols, enabling data sharing and

functional coordination. It also provides robust external interfaces (such as Integrated Bridge Systems (IBS), Voyage Data Recorders (VDR), ship

networks, and shore-based support). This deep integration and intelligent control capability not only substantially reduces crew workload and

enables efficient, reliable unmanned operation, but also optimizes equipment maintenance and improves energy efficiency through comprehensive

data monitoring and analysis. As a critical infrastructure driving vessels toward intelligence and networking, IAMCS provides a solid foundation for

safe, economical, and efficient vessel operations.

Features :

Powerful Expansion Interfaces: Provides extensive external interfaces for seamless integration with other vessel systems.

Advanced Control Capabilities: Equipped with automatic control functions, supporting complex automatic control logic and safety interlock mechanisms

User-Friendly Interface: Offers multiple HMI options with support for personalized customization, ensuring intuitive and convenient operation;

Modularity and Integration: Features modular design, supports distributed data acquisition, and enables centralized integration of ship-wide information;

Highly Reliable Network Architecture: Employs a fiber-optic dual-ring topology and dual-redundant Ethernet design, ensuring highly stable and reliable network communication