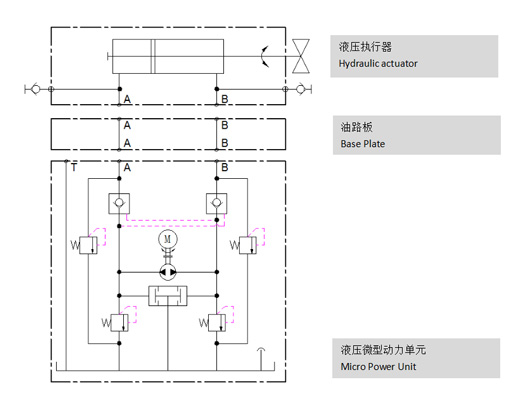

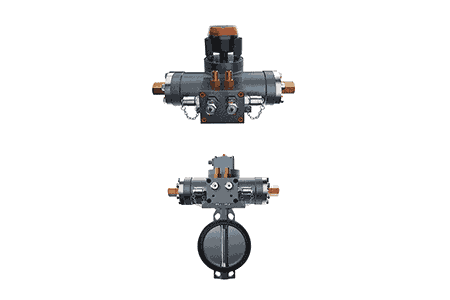

Set electrical control, hydraulic power and mechanical transmission in one, with high reliability and easy to install and use;

Compared with the electric actuator, the product has smaller volume and larger output torque at the same power.

Compared with hydraulic actuators, this product is self-contained, integrates hydraulic power unit, saves the laying of hydraulic pump station and hydraulic pipeline, saves costs, and improves the efficiency of installation and maintenance.

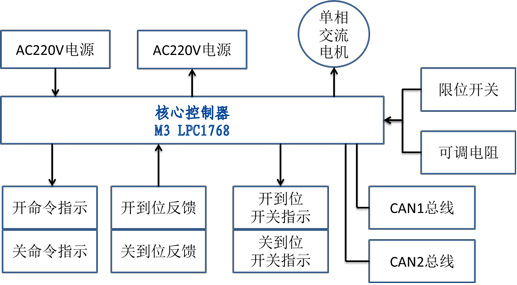

The electro-hydraulic driver covers a variety of control modes, such as switching volume, analog volume, CAN communication, etc., to meet customers' different requirements for control modes;

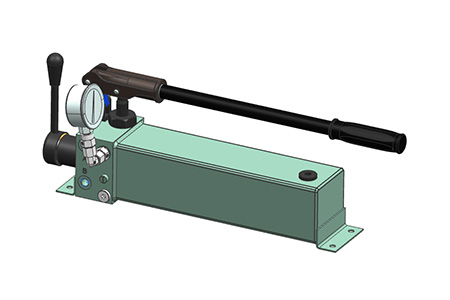

The electro-hydraulic actuator is equipped with on-site emergency operation function. In emergency case (failure or power failure), the valve can be opened and closed by moving the hand pressure pump.